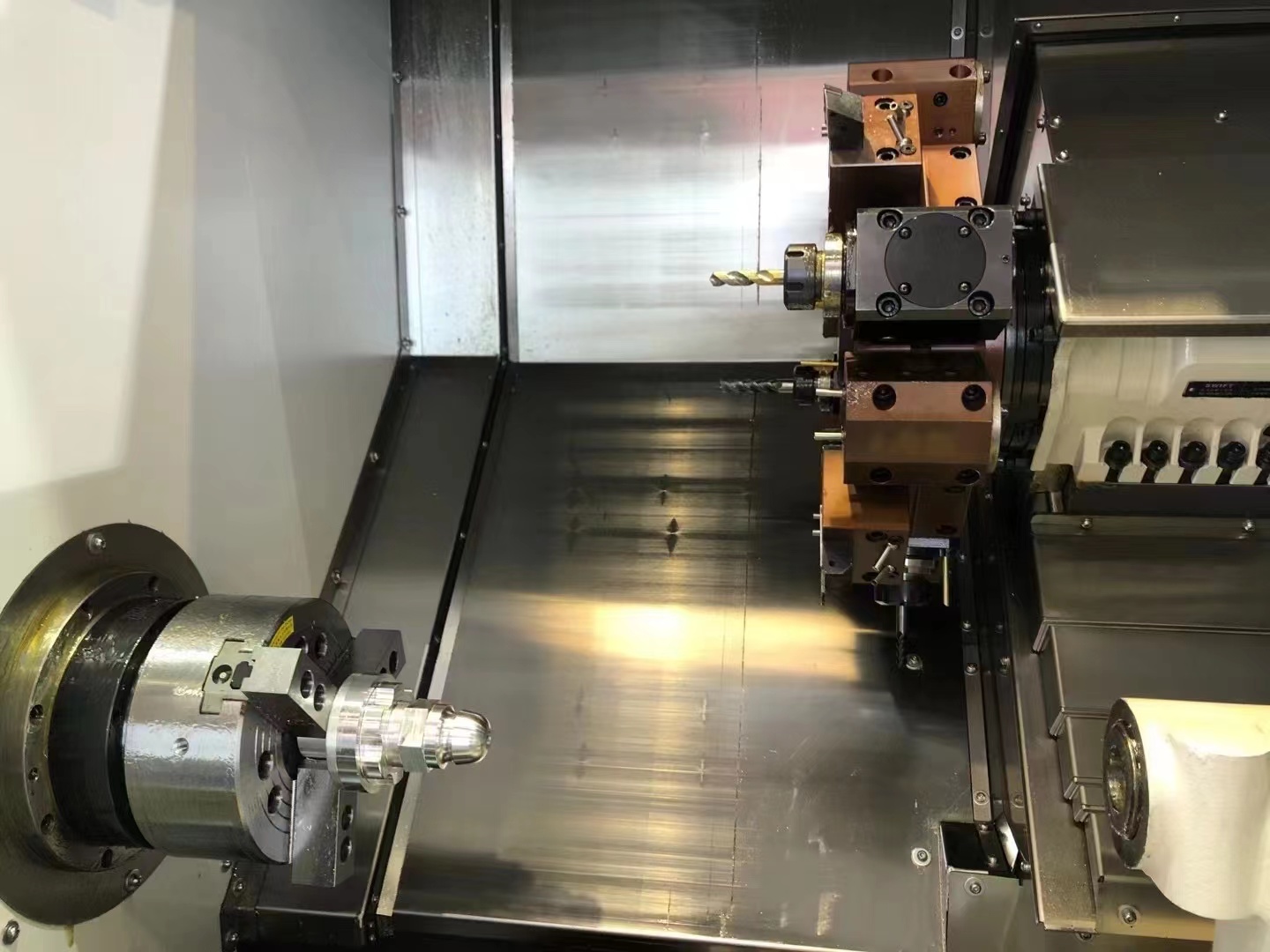

1、Y-axis:It realizes a compound function of turning and milling using an interpolated Y-axis structure,or turret with Y-axis structure.(model shall be marked with “Y”)

2、spindle:The spindle is structured with a high-power,large-torque,and high-precision sleeve,characterized by increased reduction ratio and good low-speed performance,and configured with a high-precision internal magnetic ring encoder,thereby being suitable for C-axis cutting.

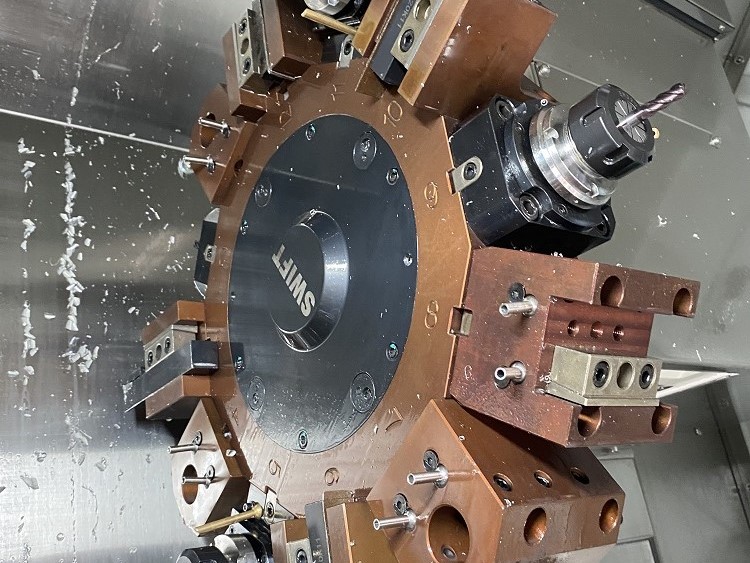

3、Turret:It is configured with the servo motor indexing, crankset positioning and hydraulic clamping mechanisms.It achieves milling-turning machining by a variety of fixed tool seats,0°,90°,and universal milling heads.

4、X/Z-axis:It is driven by a high-grade imported precision ball screw with the roller guide widened and span increased,thereby with standing heavy cutting.

5、Tailstock:Automatic programmable tailstock for easy operation and application

Item | unit | G-250MY600 | G-250MY400 | Remark | |||

Working range | Maximum spinning diameter | mm | Φ530 | ||||

Maximum turning diameter of disk parts | mm | Φ300 | |||||

Maximum machining length | mm | 600 | 400 | ||||

Saddle inclination against the level | ° | 45° | |||||

Spindle | Spindle motor | kw | 11/15(continuous/30minutes) | ||||

Spindle end | A2-6 | ||||||

Diameter of spindle through-hole | mm | Φ62 | |||||

Maximum rotational speed of spindle | r/min | 4000 | |||||

Spindle precision | mm | Radial clearance≤0.008, axial clearance≤0.005 | |||||

Coordinate axis | Maximum travel along the horizontal direction(X-axis) | mm | 275 | ||||

Maximum travel along the vertical direction(Z-axis) | mm | 670 | 470 | ||||

Maximum travel of interpolated Y-axis | mm | ±55 | |||||

X-axis serve unit | 15Nm,4000r/min | ||||||

Z-axis serve unit | 15Nm,4000r/min | ||||||

Maximum feed rate along the X-axis | m/min | 24 | |||||

Maximum feed rate along the Z-axis | m/min | 24 | |||||

Positioning precision | mm | X±0.006,Z±0.011,Y±0.006 | |||||

Repeated Positioning precision | mm | X±0.003,Z±0.003,Y±0.003 | |||||

Tool post | Type of tool post | Servo power tool post | |||||

Number of tools | 12-station | ||||||

Specification of outer diameter and end face tool holder | mm | 25X25 | |||||

Diameter of inner hole tool seat | mm | Φ32 | |||||

Specification of power unit chuck | ER32 | ||||||

Clamping device | chuck | 8"three-jaw medium hollow oil pressure chuck | |||||

Hydraulic cylinder | Medium hollow rotary cylinder | ||||||

Hydraulic tailstock | Maximum travel of centre sleeve | 100 | |||||

mm | 400 | ||||||

Taper of the center sleeve | MT5 | ||||||

Hydraulic system | Oil tank capacity | L | 60 | ||||

Hydraulic pump pressure | kg | 35 | |||||

Chip removal | Auto chip conveyor(optional) | Chain plate type chip removal conveyor and chip collecting truck | |||||

Others | Total capacity of lathe power supply | kw | 29 | 25 | |||

Boundary dimension:length x width x height | mm | 3100x1800x2000 | 2750x1800x2000 | ||||

Net weight of lathe | kg | 3800 | 3500 | ||||